Study can cheapen production of bacterial cellulose

Study can cheapen production of bacterial cellulose

A study developed by Embrapa can considerably reduce the cost of producing bacterial cellulose, a natural polymer that is considered noble but is still industrially underexplored. The scientists replaced a more expensive input, the synthetic culture medium, for one based on the fermentation of soy molasses, which had excellent yield in laboratory.

The results excited researchers due to the possibility of broadening the use of bacterial cellulose in industrial segments that could not incorporate an input that had such high costs. A cost reduction of up to 70% is expected. But this is still going to be assessed in a new study with production on a large scale.

Bacterial cellulose applicationsFoods – coconut gel (edible cellulose); antibacterial and biodegradable packaging, films, and emulsifiers Electronics – graphite nanoplates, substrate film for light-emitting diode, fuel cell membranes Biomedicine – nanofilms, structure for bone regeneration, dressings, artificial skin for wound healing, blood vessels Cosmetics – facial masks, emulsifiers, conditioners Others – clothes, accessories, camping equipment, phone cases, decoration objects Source: GAMA, Miguel; DOURADO, Fernando; BIELECKI, Stanislaw (Ed.). Bacterial nanocellulose: From biotechnology to bio-economy. Elsevier, 2016. |

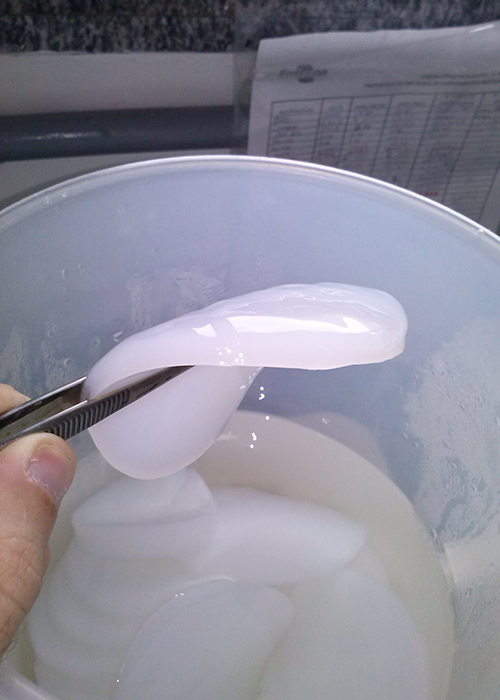

Bacterial cellulose is produced by microorganisms from a carbohydrate-rich culture medium. When compared with plant cellulose, it offers countless advantages: it is mechanically and physically more resistant, it is pure (free from lignin and hemicellulose), it can be molded into three-dimensional structures during the culture, it presents high porosity, excellent absorption power, degree of cristallinity and biocompatibility. Such characteristics make it an interesting input for the areas of medicine, pharmaceuticals, cosmetics and in the food, textile and electronics industries (see box on the side).

"It is an unique, very versatile material, but the production cost limits exploration in areas with high added value, such as the biomedical one", explains the researcher Morsyleide Rosa, a member of the team at Embrapa Tropical Agroindustry (Fortaleza, CE) that developed the study.

For years researchers have sought low cost culture mediums to increase the competitiveness of the material. One of the bets was exploring agro-industrial sources. Hence it would be possible to promote a nobler purpose for agroindustry's by-products while reducing environmental impacts.

With the soy molasses, the yield obtained in laboratory was similar to the synthetic culture mediums: around seven grams per liter after ten days of cultivation. Such yield was obtained with a fermentation medium in which the original carbohydrates cointained in soy molasses were broken into smaller molecules (hydrolysates) and supplemented with ethanol. According to researcher Fátima Borges, part of the carbohydrates present is not metabolizable by the bacteria that produce the biopolymer, hence it was necessary to perform hydrolysis to increase the availability of easily fermentable sugars.

With the soy molasses, the yield obtained in laboratory was similar to the synthetic culture mediums: around seven grams per liter after ten days of cultivation. Such yield was obtained with a fermentation medium in which the original carbohydrates cointained in soy molasses were broken into smaller molecules (hydrolysates) and supplemented with ethanol. According to researcher Fátima Borges, part of the carbohydrates present is not metabolizable by the bacteria that produce the biopolymer, hence it was necessary to perform hydrolysis to increase the availability of easily fermentable sugars.

"This formulation showed a yield that was similar to the synthetic mediums at considerably lower costs, which makes soy molasses a very favorable source for the large scale fermentation process of producing bacterial cellulose", the researcher says.

The Embrapa researcher Morsyleide Rosa recalls that the soybean chain is organized and that the stabilized material allows for easy transportation and storage. "Soy molasses is a cheap, stable and abundant culture medium", she adds. A by-product of the soybean protein industry, the molasses is used to produce feed. In the researchers' opinion, the production of bacterial cellulose would be a nobler end.

The study relied on a collaboration with State University of Londrina (UEL), which especially worked on the selection of microorganisms.

Bacterial cellulose X plant cellulose

Cellulose is the most abundant natural polymer in the world and of great economic importance. The biggest source of this material is plant cell walls, but it is also produced by fungi, protozoa and prokaryotes. Most celluloseby-products, such as paper, textiles and building materials, are made from cotton and wood. But sustainability and environmental conservation have led to the search for non-conventional alternative materials, such as bacterial cellulose.

For many industrial applications, plant cellulose is inconvenient due to its association with other biopolymer like hemicellulose and lignin. Isolating such materials requires the use of chemical products responsible for higher costs and more processing time. Meanwhile, bacterial cellulose is free of other biopolymers and can be purified through simple processes.

Another advantage of bacterial cellulose is the possibility of synthesis in little time by different kinds of microorganisms instead of long-cycle extensive agroforestry crops. The Komagataeibacter genus is of the most studied ones, but the K. xylinus species has stood out due to its high production capacity from different sources of carbon (glucose, frutose, molasses, glycerol or other organic substrata) and nitrogen. This is an important differential of the microorganism in industrial applications.

Superior properties

Bacterial cellulose is formed by very small fibres, in a nanometric scale. This gives the material superior properties compared with plant cellulose. The ribbon-shapped microfibers grant bacterial cellulose with peculiar mechanical properties, such as high resistance to traction, elasticity, durability and high water retention capacity. The polymer is capable of absorbing almost 100 times its own mass in water.

For medicine

The material is biocompatible, inert, atoxic, and non-allergenic. Dressings made from it result in better wound healing. It provides a moist environment for the wounds, presents suitable structure and resistance, and is selectively permeable. It is also promising that antimicrobial agents could be incorporated and the material could be used in several fields of the health sciences, e.g. structure for bone regeneration, drug release systems, new vascular grafts, or supports for tissue engineering.

Food

One of the first known uses of bacterial cellulose was as food. Coconut gel or nata de coco, from the Phillipines, became one of the first commercially available food products of microbial cellulose, gaining notable popularity in other Asian countries, including Indonesia, Japan and Taiwan. This product is traditionally obtained through the static fermentation of coconut water. With a jellifying texture, the polymer is not digested by the human system, a property that offers applications in the food industry, such as the manufacture of products with reduced caloric content, for instance.

Electronics

In the field of electronics, membranes with high electrical conductivity and light emitting devices were developed through the incorporation of metal into the structure of cellulose. Some of the membranes were modified with palladium and platinum to be used in fuel cells and catalytic reactors.

Photo: André Luís Sousa Pereira

Translation: Mariana Medeiros

Verônica Freire (MTb 01125/CE)

Embrapa Tropical Agroindustry

Press inquiries

agroindustria-tropical.imprensa@embrapa.br

Phone number: +55 85 3391-7116

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/