Researchers develop microorganisms to harness energy and products from biomass

Researchers develop microorganisms to harness energy and products from biomass

Photo: Jonathan Dias

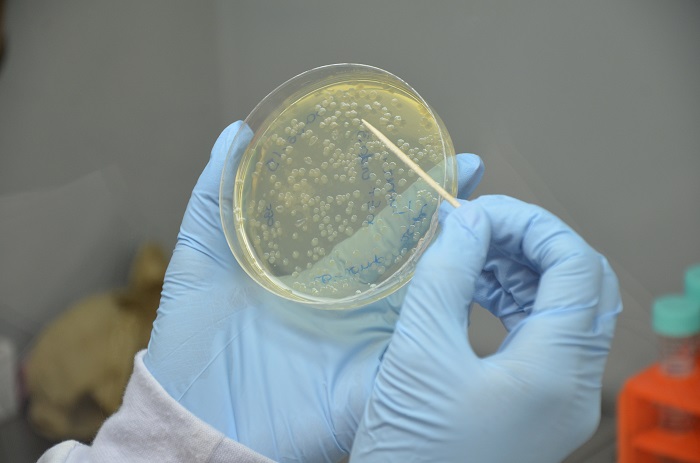

Scientists analyzed materials obtained from different environments ranging from Amazon soils to goat rumens in the Brazilian Northeast or to the intestines of insects in Argentina

Researchers from Embrapa Agroenergy (Brasília, DF) are developing national technology to obtain and transform the raw material that is most likely to be the one most used in an economy that relies less on oil byproducts. The raw material is sugars contained in leaves, stems, bagasses and other different plant parts, the so-called biomass. To convert such raw material into fuels and several other products from renewable sources, the work of the scientists is centered in the genetic engineering of microrganismos that act as biofábricas. The team obtained unknown genetic material from fungi and bacteria to use for that purpose.

The first challenge is deconstructing the plant cell wall to extract sugars, which is made with the use of a cocktail of enzymes, substances normally obtained for commercial use through microorganism cultures. Nowadays, the few cocktails available to deconstruct biomass are produced by multinationals, with imported technology. At Embrapa Agroenergy's laboratories, however, scientists have already been working with three fungi, obtained through bioprospecting and genetic engineering, whose enzymes have yielded promising results from an industrial point of view.

So far, it has taken five years of research, which started with the careful analysis of materials obtained from collections of microorganisms and samples from the most different environments - ranging from Amazon soils to goat rumens in the Brazilian Northeast or to the intestines of insects in Argentina. The researchers sought fungi and bacteria that could produce enzymes that digest cellulose. In some cases, it was not possible to cultivate the microorganisms to identify them. The team then used advanced molecular biology techniques to access their DNA and discover genes that could be useful, at a later moment, for the breeding and genetic improvement of the most promising species.

And this moment has already arrived. After a positive experience using genes patented by other institutions, Embrapa scientists are now working with the novel genetic materials. “From the beginning, the goal was to reach this stage; and we made it”, celebrates Betania Ferraz Quirino, from Embrapa Agroenergy.

Transforming xylose

The enzyme cocktails extract mostly two types of biomass sugars: glucose and xylose. The first one is simply added to sugar plant fermentation tanks and the Saccharomyces cerevisiae yeast converts it into ethanol. In turn, xylose has a different chemical structure, and the same microorganism cannot consume it to transform it into other compounds.

Ruling out xylose, however, is out of the question. It is the second most abundant type of sugar found in nature - in sugarcane bagasse, for example, it is equivalent to 33% of the biomass. Therefore, as they work in the development of enzyme cocktails to desconstruct biomass, scientists have been searching for microorganisms that can convert xylose into ethanol or other bioproducts.

In nature, there are countless beings that process xylose. The problem is finding one capable of doing that and withstanding an industrial process, in specific temperature and pressure conditions. The solution is to once again resort to genetic engineering. “We have this challenge: the microorganisms that have been adapted to the industry are not good in metabolizing xylose, while the ones that are good in converting xylose are not traditionally used in the industry. So what we have to do is to piece together those two things: xylose metabolism and industrial application”, details João Ricardo Moreira Almeida, from Embrapa Agroenergy.

The first aim of the researchers was to obtain lineages that produced ethanol from xylose - and they did. Their yield is still low, but researchers have been working to optimize it. However, they have increasingly focused on using the sugar to obtain other products with higher market value than the fuel. It is the case of organic acids widely used in the chemical and food industries.

The future is here

Using sugars instead of oil and derivatives to obtain different products is a future that has already arrived. “Sugar has already started to be the basis for different biotechnological processes for the production of chemical compounds”, Almeida observes. And hence Brazil, a major producer of the commodity at a low cost, has attracted attention.

Amyris, an American biotechnology company, has set up a branch in Brotas, SP, next to a sugarcane plant, to produce a molecule called farnesene. Once sugarcane sugar is converted into this compound by a bacterium that has been genetically modified by the company, it is turned into oil and lubricants for engines and industries. The same strategy was adopted by TerraVia, which uses microalgae instead of bacteria. And thus sugarcane is turned into other valuable types of oils, which are already especially used in cosmetics, and should reach the food and feed market soon.

The enterprises, however, utilize sugars from sugarcane juice. The expectation, and the research effort, is so that the bioeconomy is moved by biomass sugar contained in cellulose and hemicellulose from plant cell walls, which are underused today. “Cellulose is the most abundant polymer in nature”, recalls Almeida. Any agricultural crop, produced in any climate condition, for whichever purpose, has leaves, stems and bagasse from which sugar can be extracted.

So far, there have been two ethanol production units in Brazil that set out to exploit the material available in sugarcane bagasse and stubble. The first one, in Alagoas, started to operate in September 2014, but it suspended production in April 2016. At the time, it was reported that the company had been facing problems at the initial stages of the production process and that it would assess other technologies. The second unit is in Piracicaba, SP.

For Almeida, the experience of such first enterprises has shown that the process of obtaining sugars from biomass works and that it can have good outcomes. But scaling it up has also started to show new problems for the teams. “The major bottlenecks have been overcome, but the process needs to be optimized on an industrial scale”, he sums up.

The biggest challenge for national research centers is that all of those pioneering companies mainly operate with foreign technologies. For Almeida, the development of national solutions is a strategic issue.

Learn more

Click here and check Embrapa Agroenergy's technology assets for the exploitation of biomass sugars.

Translation: Mariana Medeiros

Vivian Chies (MTb 42.643/SP)

Embrapa Agroenergy

Press inquiries

agroenergia.imprensa@embrapa.br

Phone number: +55 61 3448-2264

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/