New microorganism produces enzyme of industrial interest with more sustainability

New microorganism produces enzyme of industrial interest with more sustainability

Embrapa Agroenergy (Brasília, DF) has developed a genetically modified microorganism that works as a biofactory that can produce an input used in the biofuel, food, beverage, paper and textile industries . Such input, beta-glycosidases, is a group of enzymes that work in the last stage of cellulose degradation of plants like cotton, sugarcane, and eucalyptus. The research center has filed a request to patent the technology, developed in partnership with the Federal University of Rio Grande (Furg).

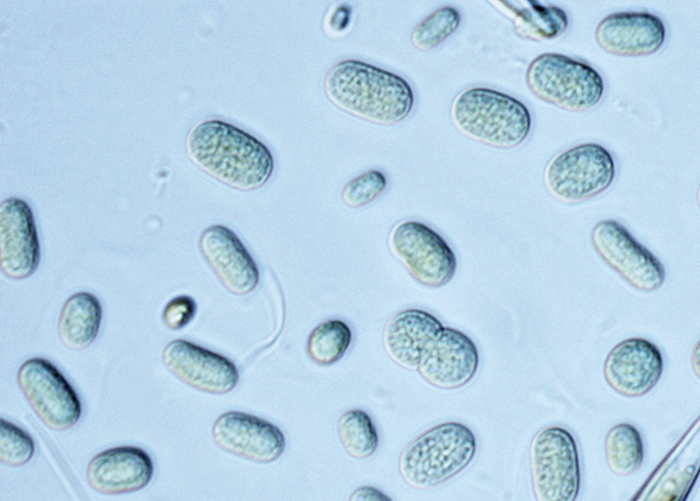

Nowadays, commercial production of beta-glycosidases is mainly made by fungi or bacteria, which need to consume sugar or another source of carbon to grow. The novelty is that the researchers have managed to have such enzymes be produced by another type of microorganism, cyanobacteria. This is advantageous precisely because they do not need to be “fed” with sugars. Similar to microalgae, they are aquatic unicellular organisms that combine microorganism and plant characteristics and perform photosynthesis. Therefore, they only need CO2 and light to grow and produce enzymes.

Embrapa Agroenergy's head of Research and Development, Bruno Brasil, explains that, because they do not need sugars or other organic carbon source, the enzyme biofactories based on cyanobacteria have potential advantages regarding production costs and scaling-up capacity. The technology is also capable of adding more sustainability to the production chains that use enzymes, since, to grow, these organisms capture CO2 from the atmosphere or from associated production processes. “They could consume the CO2 that leaves sugar and ethanol plants' fermentation vats”, Brasil exemplifies. Moreover, as they do not contain sugars, cyanobacteria culture media are less susceptible to contaminations that reduce productivity.

Amazon gene

With an eye on such advantage of replacing fungi with cyanobacteria, the researchers came across the first challenge: in nature, species capable of naturally generating significant amounts of these enzymes were not known. Thus the team soon moved on to genetic modification. To increase the production of beta-glycosidases by the selected cyanobacteria, the group used a gene found in the bacterial community of the Amazon Rainforest soil. This gene had been previously identified by another Embrapa Agroenergy team, which uses Molecular Biology techniques to access the DNA of microorganisms without cultivating them in laboratory.

With such new gene expression, the scientists managed to increase the volume of beta-glycosidase produced by the cyanobacteria eightfold. Embrapa and Furg now work to increase such productivity even more. Another line of development is enzyme engineering. With the transformation protocols they developed, the team wants to have the microorganisms generate beta-glycosidases with new properties that potentialize industrial yield. “We can make this microorganism produce a molecule that has been "engineered" from a molecular point of view so that it is a better product”, the Furg professor Luis Fernando Marins explains.

Growing market

The global enzyme market is increasing: estimates indicate that it should reach the amount of US$ 5.4 billion in 2020. Currently, detergent manufacturers are the largest consumers of such inputs, which are also often used in the production of animal feed, food, and drinks.

Investments to reduce the use of oil and increase the use of renewable raw materials in the transformation industry are paving the way for enzymes that work in the process of cellulose degradation, a group to which beta-glycosidases belong. What they do is to desconstruct the structure of cellulose in severeal stages until it is reduced to sugars such as glucose, which, in turn, can be converted into different products - from ethanol to pharmaceuticals. Improving the efficiency and reducing the cost of such enzymes are considered key for the growth of the so-called bioeconomy.

Currently, beta-glycosidases have been used in the food industries to clarify fruit juices and increase the nutritional quality of fermented products. Breweries also use them, in processes that facilitate the filtration stage. Meanwhile in the textile industries, there are different applications on cotton fabrics, such as restoring brightness.

Seeking partners

The cyanobacteria-based beta-glycosidase biofactories constitute one of the 34 technologies at an intermediate stage of development that compose Embrapa Agroenergy's Technology Showcase. The research center seeks partners for the next stages of work with this asset and with others. Bruno Brasil explains that the institution bets in open innovation to make the technologies to reach the market faster and more assertively. “In the case of the beta-glycosidase biofactories, for instance, working in cooperation with companies at the next stages to development can help us direct the engineering of enzymes toward different industrial segments”, he details. To establish the partnerships, industries can use funds from the Brazilian Research and Industrial Innovation Corporation (Embrapii), which can bear up to a third of the project costs.

Cyanobacteria and microalgae constitute one of the six industrial platforms in which Embrapa Agroenergy works. To check this one and the others, as well as the institution's axes of Research and Development, access the Unit's web page and Technology Showcase, which is available for anyone interested. Check the issue of Agroenergia em Revista on microalgae as well.

Translation: Mariana Medeiros

Vivian Chies (MTb 42.643/SP)

Embrapa Agroenergy

Press inquiries

agroenergia.imprensa@embrapa.br

Phone number: +55 61 3448-2264

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/