Biomass-fueled stove improves the life of African communities

Biomass-fueled stove improves the life of African communities

Researchers from Embrapa Forestry, in partnership with the University of Energy and Natural resources, of Sunyani, Ghana, Africa, developed a low-cost stove of the gasifier kind. The goal is to improve the quality of life of communities in the African country, which often rudimentarily prepare their foods and are subject to inhaling smoke, to extreme heat and to fuel scarcity.

The new stove not only improved issues like cooking time, ergonomy and safety, but is also capable of producing “biochar”, a soil conditioner with the use of local organic waste. The product improves the physical, physical-chemical or biological activity properties of the soil.

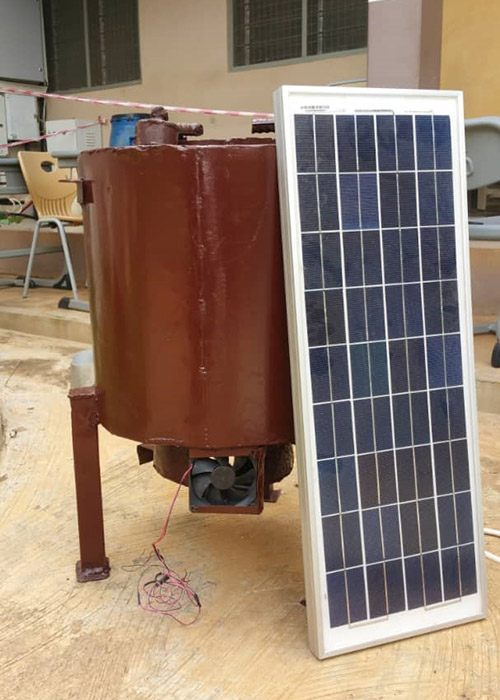

An prototype for the stove was developed between 2015 and 2016 and started with a diagnosis in 12 communities in that region. The researchers mapped the needs and developed a steel prototype composed by two chambers: an internal and an external one. The central tube receives the “fuel” made of residual biomass, which can be firewood, rice hulls, maize ears, among others, and generates heat for cooking.

The external cylinder receives the heat from the other compartment and, as there is no oxygen circulation, it carbonizes agricultural waste to generate biochar. The results include smokeless cooking fueled by agricultural waste, excellent energy efficiency and the production of na organic conditioner that will contribute to improving soil characteristics in Ghana's agricultural communities.

Faster cooking

Increasing energy efficiency was one of the ways researchers found to minimize the problem of fuel scarcity and replace the use of coal from native forests. When compared with the cookstove already used in the country, gyapa, the invention outdoes all cooking time indicators. To prepare Ghana's typical food, banku, it took 42 minutes in gyapa and only 12 in the gasifier. As for rice, the time required was cut from 33 minutes to 18.

Moreover, palm oil extraction - a source of income for the families - was also shown to be more efficient in the new equipment. While the traditional appliance needs 220 minutes, it is possible to make the same process in 150 minutes in the prototype. For the extraction, a larger version of the gasifier was created.

Another direct benefit generated by the solution offered by the researchers is ergonomy. Once used to cooking by crouching over the stove, now women can stay standing. According to data surveyed by the study, coal and firewood represent 85% of the energy used in kitchens in the country, but they are used with low efficiency and harm the health of those who work there due to smoke inhalation.

Soil improvement

To determine the possibility of using organic waste that already existed in African locations, Embrapa held lab tests with corncobs and rice hulls, monitoring their heat-producing power, volatile materials and ash content, in addition to a toxicity study with earthworms. According to the researcher Cláudia Maia, from Embrapa Forestry, corncobs proved to be better as fuel to generate energy while rice hulls, to produce biochar.

“Biochar production is the greatest feature of this project. With such material, it is possible to potencialize some soil characteristics, such as: higher water retention, increased carbon content, sustained fertility and reduced acidity”, she asserts. To potencialize the use of biochar, multiplying agents went through a workshop and further training to pass it on to local communities.

Next steps

“After the development of the prototype and tests, our goal is to move towards the development of the product on a large scale through partnerships. We need to promote its benefits and disseminate its use”, celebrates Gilbert Ayine Akolgo, professor of the University of Energy and Natural Resources and local project coordinator.

In spite of the gasifier's initial cost (32 dollars for the smaller one and 40 dollars for the larger one) being higher than gyapa, which costs 10 dollars, the expectation is that, from the use of agricultural waste at no cost, this difference can be compensated in the short and medium term. The product has also proved viable for other purposes, such as drying grains and industrial use.

Besides the environmental and social benefits generated by the project, the Embrapa researcher Cláudia Maira sees large possibilities of technology transfer to local craftsmen, entrepreneurs and farmers, creating business opportunities. “At the next stage of the project, the aim is to insert the gasifier in a sustainable system, with organic vegetable gardens and the concepts of healthy diets and zero waste”, Maia explains. Possibilities of using the equipment in vulnerable communities in Brazil were also identified. For this purpose, it will be necessary to find partners to make tests to improve the gasifier's efficiency and the raw materials that can be used, according to the researcher.

Marketplace

The project is part of the Agricultural Innovation Marketplace, a partnership between Embrapa researchers and co-leaders from institutions in Africa, Latin America and the Caribbean. The Marketplace if supported by partners like the Gates Foundation, UN's International Fund for Agricultural Development (IFAD), the World Bank, the British Department for International Development (DFID) and the Forum for Agricultural Research in Africa (FARA).

Translation: Mariana Medeiros

Katia Pichelli (MTb 3594/PR)

Embrapa Forestry

Press inquiries

florestas.imprensa@embrapa.br

Phone number: +55 41 3675-5638

Collaboration: Juliane Ferreira ((MTb 4881/PR))

Embrapa Forestry

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/