It can work as a filter membrane that can remove contaminants like heavy metals, hormones and drugs from the water . Nanoproduct could also be raw material for intelligent labels in many industries, like the food sector. It could also show whether a given product was exposed to a toxic gas, for instance. Developed by Embrapa and UFSCar, the nanoproduct is obtained through versatile low-cost processes . Unlike conventional papers that are cellulose-based, the new ceramic version with fibers on a nanometric scale is inorganic, which gives it higher mechanical and chemical resistance . Imagine a membrane that can filter contaminants that are hard to remove from water, like heavy metals. Now, consider that it can also be used to assess the quality of foods or to detect toxic gases. These are some of the potential applications of a nanomaterial as thin and flexible as a sheet of paper, which has been newly-developed by scientists from Embrapa Instrumentation and the Federal University of São Carlos (UFSCar), and which resulted in a patent request filed at the National Institute of Industrial Property (INPI). The ceramic nanopaper was obtained by combining versatile processes and became an alternative version to conventional papers, which are composed of cellulose and inorganic elements. The innovation is the result of the combined skills of researchers from the Network of Nanotechnology applied to Agribusiness (Rede AgroNano), coordinated by Embrapa Instrumentation, and counted on UFSCar's participation. Another advantage of nanopaper is that it could be used in the development of sensors for the analysis of toxic gases and food quality, whose research is already in progress at Embrapa Instrumentation. The advantage of the use of nanopaper is that it can be used both as a substratum and as its own sensorial layer at the same time, that is, it is already a complete device with a much simpler configuration than those offered by conventional chemical sensors. “The smart nanopaper also has potential to be used to manufacture food labels that could work as flexible and easily adaptable sensors. Such labels would not only contain usual information like expiration dates, but would also detect gases that indicate the food quality”, explains the researcher Daniel Souza Corrêa, who coordinated the research with Luiz Henrique Capparelli Mattoso. By using nanotechnology, an area that comprises the manipulation of matter on an atomic and molecular scale, the researchers developed nanopaper from the combination of a polymer matrix and inorganic precursors processed through the electrospinning and sol-gel techniques (check box below), followed by thermal treatment (calcination) to eliminate the organic stage. Rafaela explains that the organic stage is necessary to form fibers during the process of electrospinning and subsequently obtain the ceramic material. . What it is electrospinning and sol-gel? The electrospinning technique allows the production of beds of nanofibers whose final aspect is similar to a non-woven fabric, but such beds are composed of fibers of nanometric diameters (a thousand times smaller than a strand of hair). As such, they have high surface area, flexibility and potential chemical functionality, which are fundamental requirements for use in sensors and pollutant adsortion systems. Some of the advantages of the technique is the easiness of processing materials on a nanoscale, chemical functionality, relatively low cost, in addition to the possibility of obtaining a large variety of materials. Meanwhile sol-gel is a widely known chemical synthesis route that is used in the production of three-dimensional solid materials from small molecules. The process involves the formation of a colloidal suspension (sol stage) - which is a mix of very small particles suspended in another substance - and its further geleification in a liquid continuous stage (integrated network), forming the three-dimensional gel. “The final result is a porous, three-dimensional bed, formed by ceramic amorphous and crystalline nanofibers of different interconnected compositions, which offer excellent properties, and could be applied as transducers in chemical sensors or filter membranes.” In the scientific literature there are already some proposals of nanopaper, but most involve plant materials stemming from cellulose, unlike the composition of Embrapa-UFSCar's nanoproduct, whose final composition is inorganic. “The inorganic nanofibers give nanopaper autosustainability, flexibility, large surface area, chemical stability and preserves properties, like mechanical ones, even at higher temperatures”, details Luiza Mercante. The professor also adds that the nanopaper-based platform can be an option to remove emergent pollutants, such as heavy metals, hormones and pharmaceuticals, which require filters with specific properties for their removal. Work overcame challenges The development of nanopaper faced challenges. For Corrêa, the biggest difficulties were found in adjusting the formula (composition of reagents) and determining the parameters both for the processing stage (electrospinning technique and sol-gel), and for the post-processing (calcination) to obtain the material. “The adjustment of these parameters was fundamental to obtain a ceramic material in the shape of a “sheet of paper”, that is, thin and with good mechanical properties and large surface area”, the scientist explains. The nanopaper shows favorable structure and composition for gas detection, once its fibrous structure with high surface area is advantageous for percolation, adsorption and desorption of gases. Moreover, the nanopaper can be operationalized with other types of nanomaterials such as graphene, carbon nanotubes, metallic nanoparticles, among others, which can favor further interaction with different gases and potencialize its use as an active layer in sensors of toxic gases like ammonia, carbon dioxide, etc.”, the researchers state. Graduate participation was fundamental The research on the inorganic nanopaper, advised by Corrêa and Mattoso, was shaped during the studies of the chemists Rafaela Silveira Andre, a postdoctoral candidate at Embrapa, and Luiza Amim Mercante, then a postdoctoral student at UFSCar and now a professor of the Federal University of Bahia (UFBA), and of the PhD student from UFSCar's Graduate Chemistry Program (PPGQ) Murilo Enrique Moreira Facure. During the work, Rafaela André also interned at the Massachusetts Institute of Technology (MIT), in the United States, with funds from the São Paulo Research Foundation (Fapesp). Translation: Mariana Medeiros

Photo: iStock

![iStock - Nanotechnology, an area in which matter is manipulated on an atomic and molecular scale, was the basis for the development of nanopaper. The final composition of the product is inorganic, unlike previous ones in the scientific literature iStock - Nanotechnology, an area in which matter is manipulated on an atomic and molecular scale, was the basis for the development of nanopaper. The final composition of the product is inorganic, unlike previous ones in the scientific literature]()

Nanotechnology, an area in which matter is manipulated on an atomic and molecular scale, was the basis for the development of nanopaper. The final composition of the product is inorganic, unlike previous ones in the scientific literature

-

It can work as a filter membrane that can remove contaminants like heavy metals, hormones and drugs from the water . -

Nanoproduct could also be raw material for intelligent labels in many industries, like the food sector. -

It could also show whether a given product was exposed to a toxic gas, for instance. -

Developed by Embrapa and UFSCar, the nanoproduct is obtained through versatile low-cost processes . -

Unlike conventional papers that are cellulose-based, the new ceramic version with fibers on a nanometric scale is inorganic, which gives it higher mechanical and chemical resistance . |

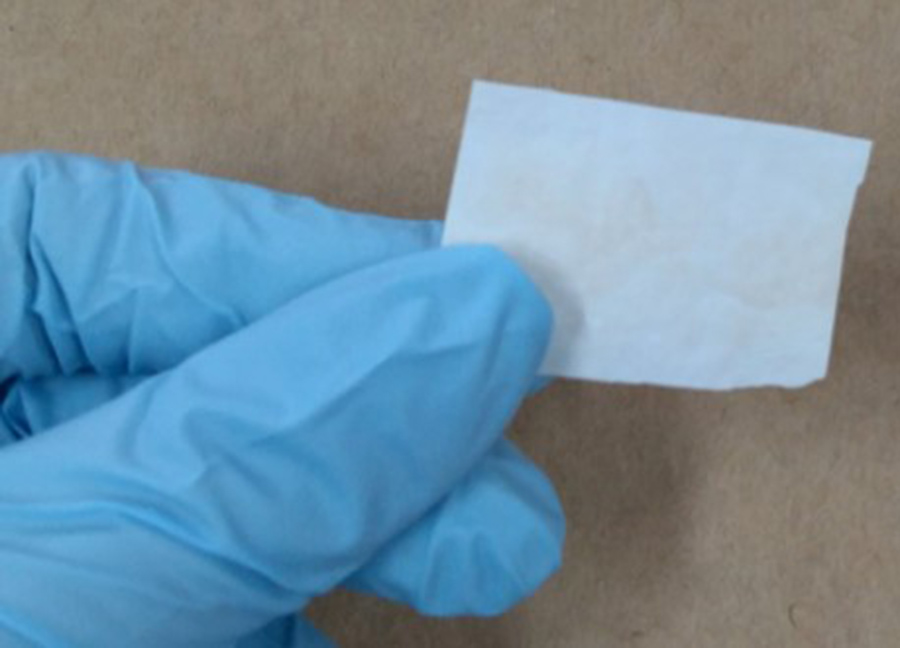

Imagine a membrane that can filter contaminants that are hard to remove from water, like heavy metals. Now, consider that it can also be used to assess the quality of foods or to detect toxic gases. These are some of the potential applications of a nanomaterial as thin and flexible as a sheet of paper, which has been newly-developed by scientists from Embrapa Instrumentation and the Federal University of São Carlos (UFSCar), and which resulted in a patent request filed at the National Institute of Industrial Property (INPI).

The ceramic nanopaper was obtained by combining versatile processes and became an alternative version to conventional papers, which are composed of cellulose and inorganic elements. The innovation is the result of the combined skills of researchers from the Network of Nanotechnology applied to Agribusiness (Rede AgroNano), coordinated by Embrapa Instrumentation, and counted on UFSCar's participation.

Another advantage of nanopaper is that it could be used in the development of sensors for the analysis of toxic gases and food quality, whose research is already in progress at Embrapa Instrumentation. The advantage of the use of nanopaper is that it can be used both as a substratum and as its own sensorial layer at the same time, that is, it is already a complete device with a much simpler configuration than those offered by conventional chemical sensors.

“The smart nanopaper also has potential to be used to manufacture food labels that could work as flexible and easily adaptable sensors. Such labels would not only contain usual information like expiration dates, but would also detect gases that indicate the food quality”, explains the researcher Daniel Souza Corrêa, who coordinated the research with Luiz Henrique Capparelli Mattoso.

“The smart nanopaper also has potential to be used to manufacture food labels that could work as flexible and easily adaptable sensors. Such labels would not only contain usual information like expiration dates, but would also detect gases that indicate the food quality”, explains the researcher Daniel Souza Corrêa, who coordinated the research with Luiz Henrique Capparelli Mattoso.

By using nanotechnology, an area that comprises the manipulation of matter on an atomic and molecular scale, the researchers developed nanopaper from the combination of a polymer matrix and inorganic precursors processed through the electrospinning and sol-gel techniques (check box below), followed by thermal treatment (calcination) to eliminate the organic stage. Rafaela explains that the organic stage is necessary to form fibers during the process of electrospinning and subsequently obtain the ceramic material. .

What it is electrospinning and sol-gel? The electrospinning technique allows the production of beds of nanofibers whose final aspect is similar to a non-woven fabric, but such beds are composed of fibers of nanometric diameters (a thousand times smaller than a strand of hair). As such, they have high surface area, flexibility and potential chemical functionality, which are fundamental requirements for use in sensors and pollutant adsortion systems. Some of the advantages of the technique is the easiness of processing materials on a nanoscale, chemical functionality, relatively low cost, in addition to the possibility of obtaining a large variety of materials. Meanwhile sol-gel is a widely known chemical synthesis route that is used in the production of three-dimensional solid materials from small molecules. The process involves the formation of a colloidal suspension (sol stage) - which is a mix of very small particles suspended in another substance - and its further geleification in a liquid continuous stage (integrated network), forming the three-dimensional gel. |

“The final result is a porous, three-dimensional bed, formed by ceramic amorphous and crystalline nanofibers of different interconnected compositions, which offer excellent properties, and could be applied as transducers in chemical sensors or filter membranes.”

In the scientific literature there are already some proposals of nanopaper, but most involve plant materials stemming from cellulose, unlike the composition of Embrapa-UFSCar's nanoproduct, whose final composition is inorganic. “The inorganic nanofibers give nanopaper autosustainability, flexibility, large surface area, chemical stability and preserves properties, like mechanical ones, even at higher temperatures”, details Luiza Mercante.

The professor also adds that the nanopaper-based platform can be an option to remove emergent pollutants, such as heavy metals, hormones and pharmaceuticals, which require filters with specific properties for their removal.

Work overcame challenges

The development of nanopaper faced challenges. For Corrêa, the biggest difficulties were found in adjusting the formula (composition of reagents) and determining the parameters both for the processing stage (electrospinning technique and sol-gel), and for the post-processing (calcination) to obtain the material.

“The adjustment of these parameters was fundamental to obtain a ceramic material in the shape of a “sheet of paper”, that is, thin and with good mechanical properties and large surface area”, the scientist explains.

The nanopaper shows favorable structure and composition for gas detection, once its fibrous structure with high surface area is advantageous for percolation, adsorption and desorption of gases. Moreover, the nanopaper can be operationalized with other types of nanomaterials such as graphene, carbon nanotubes, metallic nanoparticles, among others, which can favor further interaction with different gases and potencialize its use as an active layer in sensors of toxic gases like ammonia, carbon dioxide, etc.”, the researchers state.

Graduate participation was fundamental Graduate participation was fundamental

The research on the inorganic nanopaper, advised by Corrêa and Mattoso, was shaped during the studies of the chemists Rafaela Silveira Andre, a postdoctoral candidate at Embrapa, and Luiza Amim Mercante, then a postdoctoral student at UFSCar and now a professor of the Federal University of Bahia (UFBA), and of the PhD student from UFSCar's Graduate Chemistry Program (PPGQ) Murilo Enrique Moreira Facure. During the work, Rafaela André also interned at the Massachusetts Institute of Technology (MIT), in the United States, with funds from the São Paulo Research Foundation (Fapesp). |

Translation: Mariana Medeiros

Joana Silva (MTb 19.554/SP)

Embrapa Instrumentation

Press inquiries

instrumentacao.imprensa@embrapa.br

Phone number: +55 16 99994-6160

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/

“The smart nanopaper also has potential to be used to manufacture food labels that could work as flexible and easily adaptable sensors. Such labels would not only contain usual information like expiration dates, but would also detect gases that indicate the food quality”, explains the researcher Daniel Souza Corrêa, who coordinated the research with Luiz Henrique Capparelli Mattoso.