Nanotechnological dressing is able to slowly release the active ingredient contained within it. The base of the developed product is curcumin, a substance obtained from turmeric. Curcumin presents bactericidal, antioxidant, and anti-inflammatory activities. In laboratory, the dressing presented strong antimicrobial activity against Staphylococcus aureus, bacteria commonly associated with skin infections. The obtained result paves the way to widen the use of multifunctional dressings that slowly release bioactive compounds for the treatment of wounds like ulcers and burns. Researchers look for partners interested in advancing product development and conducting full-scale market testing. It is from the combination of nanotechnology and biotechnology, biodegradable composites, and a portion of curcumin – a substance found in turmeric powder – that researchers from the city of São Carlos (São Paulo, Brazil) designed a new multifunctional skin dressing for wound treatment. Besides bypassing the limitations of curcumin use, the dressing offers controlled release of the active ingredient, which does not always happen in traditional versions. Although curcumin presents several medicinal properties, such as bactericidal, antioxidant, and anti-inflammatory activities, its application is limited by its low solubility and fast degradability in the presence of light. To overcome these barriers, the researchers created a nanomaterial based on bilayer polymeric membranes, composed of electrospun fibers made of polylactic acid (PAL) and natural rubber (NR). The obtained result paves the way to widen the use of multifunctional dressings that slowly release bioactive compounds for the treatment of burns and ulcers, for example. In laboratory tests, the dressing prevented the penetration of bacteria for ten days and showed strong antibacterial action against Staphylococcus aureus, bacteria that are usually present in cutaneous wounds and associated with skin infections. The dressing may be applied as nanofiber mats, in different formats, on skin wounds. At the same time it protects injuries from external actions, such as exposure to sunlight and contamination, the dressing also reduces infection by bacteria. With a patent application already filed at Brazilian National Institute of Industrial Property (INPI), the next step is to prospect partners who are interested in advancing product development and conducting full-scale market testing. The team and the research The research was guided by the researcher of Embrapa Instrumentation, Daniel Souza Corrêa, within the Brazilian National Network of Nanotechnology for Agribusiness (AgroNano Network), and involved two graduate programs of Federal University of São Carlos (UFSCar). At the Biotechnology program (PPGBiotec), Paulo Augusto Marques Chagas developed the study on the skin dressing to obtain his doctor’s degree. The other contribution to the research came from the chemistry area (PPGQ), with the participation of the doctoral student Rodrigo Schneider, as well as of Danilo Martins, a post-doctoral student of Brazilian National Laboratory of Nanotechnology for Agribusiness (LNNA), headquartered at Embrapa Instrumentation, located in the municipality of São Carlos, in the state of São Paulo, Brazil. Researchers of the Institute of Physics of São Carlos, of University of São Paulo (IFSC-USP), aided in the characterization of the materials used for the dressing. The work focused on the development of polymer fiber mats – obtained through the electrospinning technique using a blend of polymers, such as PLA and NR containing curcumin – to be applied as dressings to help in the healing process of wounds. The asymmetrical nanofibers used are like a 3D structure with a PLA electrospun mat on the top and an electrospun mat with the PLA/NR blend containing different concentrations of curcumin on the bottom. The researchers share that understanding and controlling the material in a nanoscale, driven by the advances in the researches developed by LNNA, enabled the fusion of two areas of knowledge: materials and biotechnology. The result of this union was the skin dressing, whose research was supported by São Paulo Research Foundation (FAPESP), Coordination for the Improvement of Higher Education Personnel (CAPES), and the Brazilian National Council for Scientific and Technological Development (CNPq). The researchers used agar disk diffusion, a simple and semi-quantitative method, to determine the antibacterial activity against Staphylococcus aureus (see photo), as well as tests using swine skin to simulate an infected wound. In addition to experiments on a laboratory scale to develop the asymmetric membranes for the dressings, in vitro tests were also carried out to check curcumin release. The tests also aimed to ensure the protection of curcumin – a photosensitive bioactive compound encapsulated in the nanofibers – against the action of light and of the wound against external bacteria, whose entry is deterred by the asymmetrical membranes formed by the nanofibers. The next stages involve searches for partners to advance in the studies, aiming to check the efficacy of the dressing through in vivo tests and to improve the process to upscale production. Double-layer protection The pilot model presents important properties such as flexibility and elasticity, as well as biodegradability, biocompatibility, and the ability to perform gas exchanges, which help in the healing process of the skin. These advantageous characteristics are due to the composition and design of the polymeric nanofibers that make up the dressing. These nanofibers are formed by two membranes produced through electrospinning, each with different functions. Côrrea explains that the bottom layer, which comes into contact with the skin, is composed of a biodegradable mixture of PLA and NR that contains the bioactive compound curcumin. “The top layer, exposed to the external environment and composed only of PLA nanofibers, has a double purpose: to protect the curcumin contained in the bottom layer against photodegradation and to avoid the penetration of external bacteria”, explains the researcher. From spice to medicine Plants or plant parts have been used for medicinal purposes since prehistoric times. First, in a more empirical way, and now, in modern society, through studies on the active ingredients of plant sources, such as the curcumin ones that were used successfully in the skin dressing. According to Daniel Corrêa from Embrapa, the dressings made up of natural products work as much more than a physical barrier against the microorganisms present in the environment. “They should also prevent wound infection, maintain an adequately moist environment, allow gas exchange and nutrient transportation, minimize the pain felt by the patient, and stimulate the healing process”, he explains. However, the researcher points out that even with the great advances in the past few years, the development of wound dressings with multifunctional properties, including anti-inflammatory, antibacterial, and angiogenic (formation of new blood vessels) activities, as proposed in the research, is still a challenge to be overcome. Curcumin is the substance responsible for the yellow-orange color of Curcuma longa or turmeric, which has been used for centuries in Eastern and Asian cultures. Originating from India, which is its largest producer and consumer, turmeric is an icon of local cuisine and customs; as it is used in the famous curry powder, it has conquered palates worldwide and is used in different dishes. In Brazil, the municipality of Mara Rosa, in the state of Goiás, is considered the capital of turmeric. The spice there not only has high quality but also a high curcumin content. The substance has been attracting the interest of Western science due to its application potential and versatility, which ranges from the food industry to the medical field due to its medicinal properties. Use of combined polymers Currently, about 75 natural or synthetic polymers are used to produce nanofibers through electrospinning. Paulo Chagas clarifies that the choice of a polymer or combination of polymers as blends varies according to the application and the mechanical, thermal, and biological properties of the product. “Among the natural polymers, the latex extracted from the rubber tree (Hevea brasiliensis) – composed partially of natural rubber, water, proteins, and lipids – has been widely used as a biomaterial due to its physical properties, biocompatibility, absence of toxicity, induction of angiogenesis, and capacity of repairing tissues. The material has been perceived as a potential dressing with controlled release”, assesses the biotechnological engineer. PLA is a semicrystalline or amorphous biopolymer that is biocompatible and biodegradable and can be used for different applications, including food packaging, air filters, and controlled drug release. It is derived from the fermentation of renewable sources such as cornstarch, sugarcane and potato, produced on a large scale, and considered a possible substitute for polymers originated from nonrenewable sources. "Because of these properties and characteristics, PLA has been widely used in the production of nanofibers for the release of several compounds such as essential oils, antibacterial agents, among others”, adds Chagas. Versatility of the electrospinning technique The electrospinning technique used to produce the bilayer membrane is a well-known method to manufacture polymeric and composite nanofibers, and it has been showing great potential in the design of many biomaterials due to its simplicity, cost-effectiveness, and versatility. Nanofibers obtained through electrospinning present interesting mechanical properties, high porosity, large surface area, possibility of production upscaling, and functionalization before or after nanofiber production, besides allowing the encapsulation of numerous compounds. This allows maintaining moisture balance on the surface of the wound, gas permeation, and nutrient transportation, which are important characteristics for the healing process of skin wounds. Nanofibers can be used for skin dressings, tissue engineering, water treatment, and sensors, as well as a vehicle for releasing several antibiotics and proteins. “Therefore, the proposed approach shows an advance in the use of micro- and nanofibers for the development of multifunctional dressings that protect active compounds – such as medicinal substances, antioxidants, growth factor systems, among others – from photodegradation and that prevent external bacteria from penetrating into the wound”, says Corrêa. Chagas believes that, based on this research, new optimizations can be carried out to obtain smaller-diameter fibers from the polymeric matrices developed in the project. In his opinion, new materials can be encapsulated in the polymeric matrix, targeting different properties for improved mechanical and electrical properties that allow the fibers to act as sensors or wearable biosensors, for example. “The antioxidant potential of the developed asymmetrical membranes (see photo) can also be investigated for application in food packaging, mainly due to the photoprotection both for curcumin and the packaged food”, he concludes. The research Bilayered electrospun membranes composed of poly(lactic-acid)/natural rubber: A strategy against curcumin photodegradation for wound dressing application is presented as a scientific article in Journal Reactive & Functional Polymers, published by Elsevier.

Photo: Paulo Chagas

The multifunctional dressing, with a strong antibacterial action, slowly releases bioactive compounds for wound treatment

-

Nanotechnological dressing is able to slowly release the active ingredient contained within it. -

The base of the developed product is curcumin, a substance obtained from turmeric. -

Curcumin presents bactericidal, antioxidant, and anti-inflammatory activities. -

In laboratory, the dressing presented strong antimicrobial activity against Staphylococcus aureus, bacteria commonly associated with skin infections. -

The obtained result paves the way to widen the use of multifunctional dressings that slowly release bioactive compounds for the treatment of wounds like ulcers and burns. -

Researchers look for partners interested in advancing product development and conducting full-scale market testing. |

It is from the combination of nanotechnology and biotechnology, biodegradable composites, and a portion of curcumin – a substance found in turmeric powder – that researchers from the city of São Carlos (São Paulo, Brazil) designed a new multifunctional skin dressing for wound treatment. Besides bypassing the limitations of curcumin use, the dressing offers controlled release of the active ingredient, which does not always happen in traditional versions.

Although curcumin presents several medicinal properties, such as bactericidal, antioxidant, and anti-inflammatory activities, its application is limited by its low solubility and fast degradability in the presence of light. To overcome these barriers, the researchers created a nanomaterial based on bilayer polymeric membranes, composed of electrospun fibers made of polylactic acid (PAL) and natural rubber (NR).

The obtained result paves the way to widen the use of multifunctional dressings that slowly release bioactive compounds for the treatment of burns and ulcers, for example.

In laboratory tests, the dressing prevented the penetration of bacteria for ten days and showed strong antibacterial action against Staphylococcus aureus, bacteria that are usually present in cutaneous wounds and associated with skin infections.

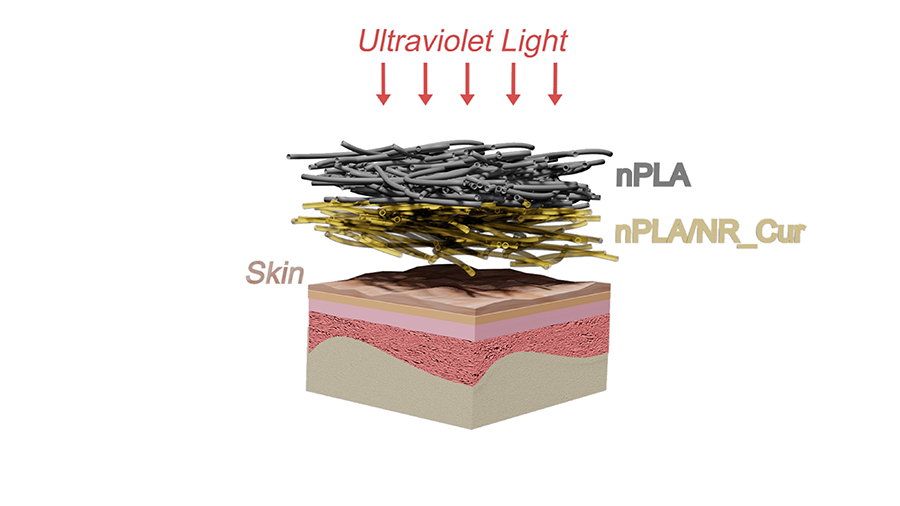

The dressing may be applied as nanofiber mats, in different formats, on skin wounds. At the same time it protects injuries from external actions, such as exposure to sunlight and contamination, the dressing also reduces infection by bacteria.

With a patent application already filed at Brazilian National Institute of Industrial Property (INPI), the next step is to prospect partners who are interested in advancing product development and conducting full-scale market testing.

The team and the research The team and the research

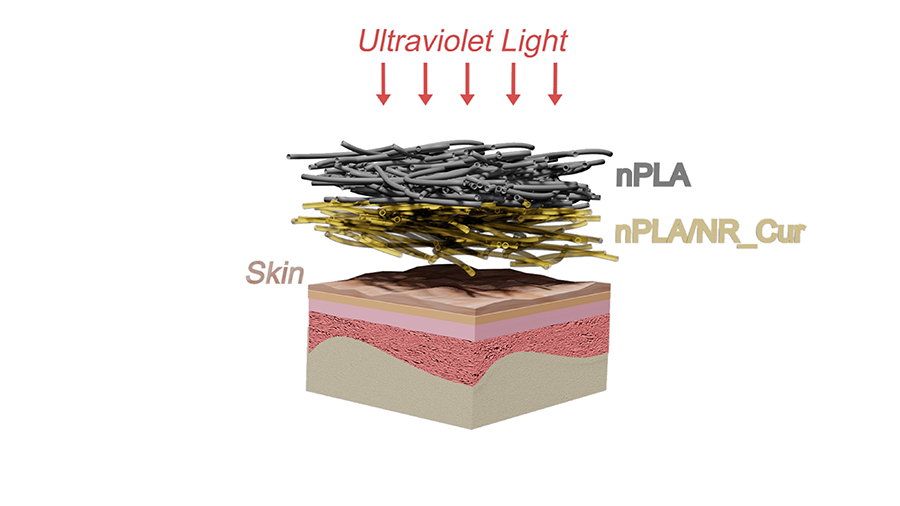

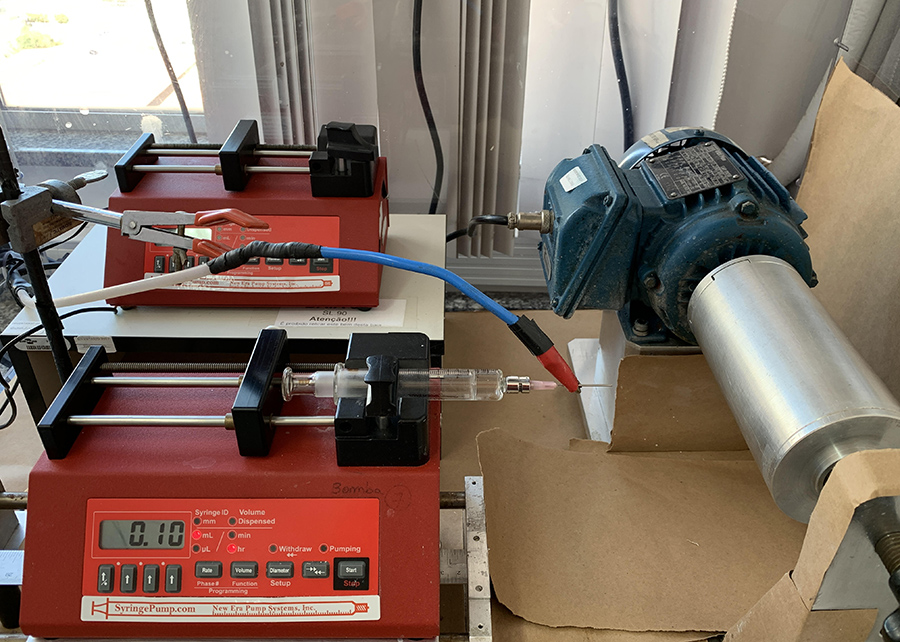

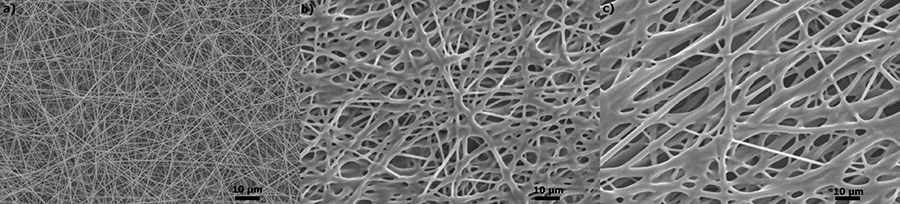

The research was guided by the researcher of Embrapa Instrumentation, Daniel Souza Corrêa, within the Brazilian National Network of Nanotechnology for Agribusiness (AgroNano Network), and involved two graduate programs of Federal University of São Carlos (UFSCar). At the Biotechnology program (PPGBiotec), Paulo Augusto Marques Chagas developed the study on the skin dressing to obtain his doctor’s degree. The other contribution to the research came from the chemistry area (PPGQ), with the participation of the doctoral student Rodrigo Schneider, as well as of Danilo Martins, a post-doctoral student of Brazilian National Laboratory of Nanotechnology for Agribusiness (LNNA), headquartered at Embrapa Instrumentation, located in the municipality of São Carlos, in the state of São Paulo, Brazil. Researchers of the Institute of Physics of São Carlos, of University of São Paulo (IFSC-USP), aided in the characterization of the materials used for the dressing. The work focused on the development of polymer fiber mats – obtained through the electrospinning technique using a blend of polymers, such as PLA and NR containing curcumin – to be applied as dressings to help in the healing process of wounds. The asymmetrical nanofibers used are like a 3D structure with a PLA electrospun mat on the top and an electrospun mat with the PLA/NR blend containing different concentrations of curcumin on the bottom. The researchers share that understanding and controlling the material in a nanoscale, driven by the advances in the researches developed by LNNA, enabled the fusion of two areas of knowledge: materials and biotechnology.  The result of this union was the skin dressing, whose research was supported by São Paulo Research Foundation (FAPESP), Coordination for the Improvement of Higher Education Personnel (CAPES), and the Brazilian National Council for Scientific and Technological Development (CNPq). The result of this union was the skin dressing, whose research was supported by São Paulo Research Foundation (FAPESP), Coordination for the Improvement of Higher Education Personnel (CAPES), and the Brazilian National Council for Scientific and Technological Development (CNPq).

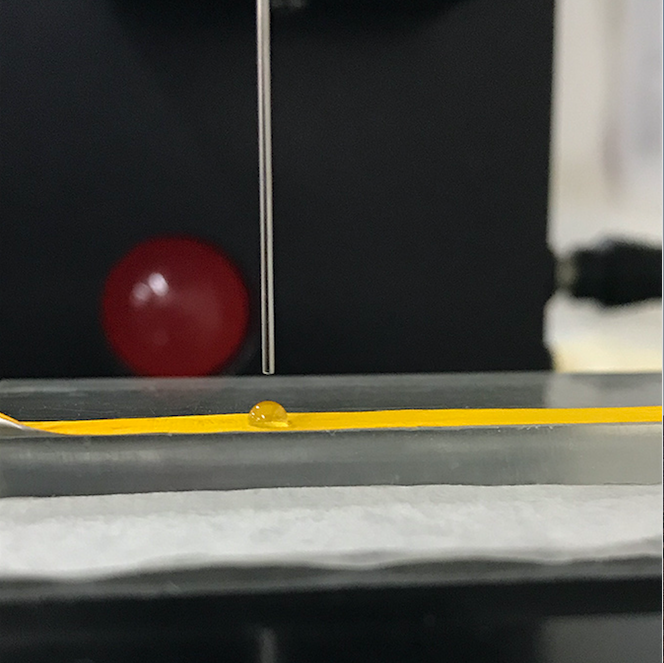

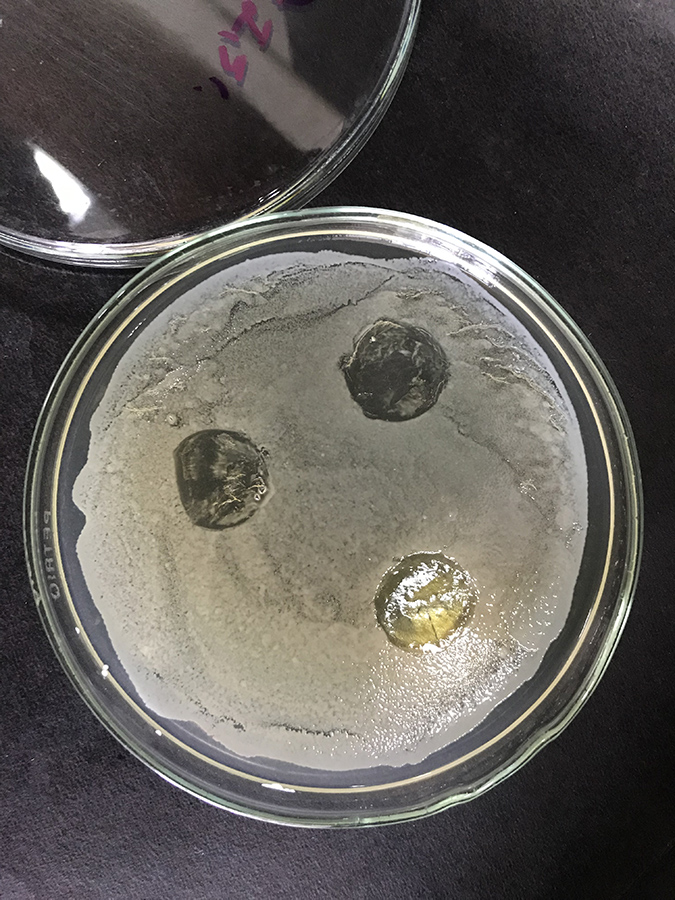

The researchers used agar disk diffusion, a simple and semi-quantitative method, to determine the antibacterial activity against Staphylococcus aureus (see photo), as well as tests using swine skin to simulate an infected wound. In addition to experiments on a laboratory scale to develop the asymmetric membranes for the dressings, in vitro tests were also carried out to check curcumin release. The tests also aimed to ensure the protection of curcumin – a photosensitive bioactive compound encapsulated in the nanofibers – against the action of light and of the wound against external bacteria, whose entry is deterred by the asymmetrical membranes formed by the nanofibers. The next stages involve searches for partners to advance in the studies, aiming to check the efficacy of the dressing through in vivo tests and to improve the process to upscale production. |

Double-layer protection

Double-layer protection

The pilot model presents important properties such as flexibility and elasticity, as well as biodegradability, biocompatibility, and the ability to perform gas exchanges, which help in the healing process of the skin.

These advantageous characteristics are due to the composition and design of the polymeric nanofibers that make up the dressing. These nanofibers are formed by two membranes produced through electrospinning, each with different functions.

Côrrea explains that the bottom layer, which comes into contact with the skin, is composed of a biodegradable mixture of PLA and NR that contains the bioactive compound curcumin. “The top layer, exposed to the external environment and composed only of PLA nanofibers, has a double purpose: to protect the curcumin contained in the bottom layer against photodegradation and to avoid the penetration of external bacteria”, explains the researcher.

From spice to medicine From spice to medicine

Plants or plant parts have been used for medicinal purposes since prehistoric times. First, in a more empirical way, and now, in modern society, through studies on the active ingredients of plant sources, such as the curcumin ones that were used successfully in the skin dressing. According to Daniel Corrêa from Embrapa, the dressings made up of natural products work as much more than a physical barrier against the microorganisms present in the environment. “They should also prevent wound infection, maintain an adequately moist environment, allow gas exchange and nutrient transportation, minimize the pain felt by the patient, and stimulate the healing process”, he explains. However, the researcher points out that even with the great advances in the past few years, the development of wound dressings with multifunctional properties, including anti-inflammatory, antibacterial, and angiogenic (formation of new blood vessels) activities, as proposed in the research, is still a challenge to be overcome. Curcumin is the substance responsible for the yellow-orange color of Curcuma longa or turmeric, which has been used for centuries in Eastern and Asian cultures. Originating from India, which is its largest producer and consumer, turmeric is an icon of local cuisine and customs; as it is used in the famous curry powder, it has conquered palates worldwide and is used in different dishes. In Brazil, the municipality of Mara Rosa, in the state of Goiás, is considered the capital of turmeric. The spice there not only has high quality but also a high curcumin content. The substance has been attracting the interest of Western science due to its application potential and versatility, which ranges from the food industry to the medical field due to its medicinal properties. |

Use of combined polymers

Currently, about 75 natural or synthetic polymers are used to produce nanofibers through electrospinning. Paulo Chagas clarifies that the choice of a polymer or combination of polymers as blends varies according to the application and the mechanical, thermal, and biological properties of the product.

“Among the natural polymers, the latex extracted from the rubber tree (Hevea brasiliensis) – composed partially of natural rubber, water, proteins, and lipids – has been widely used as a biomaterial due to its physical properties, biocompatibility, absence of toxicity, induction of angiogenesis, and capacity of repairing tissues. The material has been perceived as a potential dressing with controlled release”, assesses the biotechnological engineer.

PLA is a semicrystalline or amorphous biopolymer that is biocompatible and biodegradable and can be used for different applications, including food packaging, air filters, and controlled drug release. It is derived from the fermentation of renewable sources such as cornstarch, sugarcane and potato, produced on a large scale, and considered a possible substitute for polymers originated from nonrenewable sources.

"Because of these properties and characteristics, PLA has been widely used in the production of nanofibers for the release of several compounds such as essential oils, antibacterial agents, among others”, adds Chagas.

Versatility of the electrospinning technique Versatility of the electrospinning technique

The electrospinning technique used to produce the bilayer membrane is a well-known method to manufacture polymeric and composite nanofibers, and it has been showing great potential in the design of many biomaterials due to its simplicity, cost-effectiveness, and versatility. Nanofibers obtained through electrospinning present interesting mechanical properties, high porosity, large surface area, possibility of production upscaling, and functionalization before or after nanofiber production, besides allowing the encapsulation of numerous compounds. This allows maintaining moisture balance on the surface of the wound, gas permeation, and nutrient transportation, which are important characteristics for the healing process of skin wounds. Nanofibers can be used for skin dressings, tissue engineering, water treatment, and sensors, as well as a vehicle for releasing several antibiotics and proteins. “Therefore, the proposed approach shows an advance in the use of micro- and nanofibers for the development of multifunctional dressings that protect active compounds – such as medicinal substances, antioxidants, growth factor systems, among others – from photodegradation and that prevent external bacteria from penetrating into the wound”, says Corrêa. Chagas believes that, based on this research, new optimizations can be carried out to obtain smaller-diameter fibers from the polymeric matrices developed in the project. In his opinion, new materials can be encapsulated in the polymeric matrix, targeting different properties for improved mechanical and electrical properties that allow the fibers to act as sensors or wearable biosensors, for example.  “The antioxidant potential of the developed asymmetrical membranes (see photo) can also be investigated for application in food packaging, mainly due to the photoprotection both for curcumin and the packaged food”, he concludes. “The antioxidant potential of the developed asymmetrical membranes (see photo) can also be investigated for application in food packaging, mainly due to the photoprotection both for curcumin and the packaged food”, he concludes.

The research Bilayered electrospun membranes composed of poly(lactic-acid)/natural rubber: A strategy against curcumin photodegradation for wound dressing application is presented as a scientific article in Journal Reactive & Functional Polymers, published by Elsevier. |

Joana Silva (MTb 19.554/SP)

Embrapa Instrumentation

Press inquiries

instrumentacao.imprensa@embrapa.br

Phone number: +55 16 99994 6160

Translation: Micla de Souza and Ana Beatriz Linhares

Secretariat of Research and Development

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/

Double-layer protection

Double-layer protection