The products include airy and crispy wholegrain snack puffs; pre-cooked flours for domestic or industrial purposes; pasta; and a pita bread recipe. Embrapa is looking for partners for co-development, validation, industrial scale-up and licensing aimed at commercial exploitation. The foods were obtained through thermoplastic extrusion, a process that allows for the full use of cereals and pulses, and a technology Embrapa has broad experience in. The results found 12.8% protein content for the snack and 10.5% for the pita bread, and 9% dietary fiber content for the snack and 10% for the pita bread. The pasta, namely fusilli, has higher protein (13%) and dietary fiber (11%) contents than most commercially available products. Embrapa Food Technology is looking for partners to take new gluten-free food options, which combine whole cereals (rice and millet) and pulses (chickpeas and beans), to the market. The products include airy and crispy whole grain snack puffs; pre-cooked wholemeal flours for domestic or industrial purposes; whole grain pasta; and a pita bread formulation. Such technological assets are available for co-development, validation, industrial scale-up and licensing (See more details in the box at the end of this piece). The results were achieved through the use of thermoplastic extrusion, a quick and versatile manufacturing process that forms different shapes and textures. According to the Embrapa researcher Carlos Piler, thermoplastic extrusion also allows the processing of the whole grains without separating them from their husks, as is the case in refined flours. As a result, the enzymes that cause rancidity are inactivated, extending product shelf life. “The choice of this process is strategic in the processing of whole foods, as the grains of cereals or pulses are fully used. Moreover, Embrapa has years of experience with the technology in the development of foods from a range of plant raw materials”, he informs. The researcher also explains that both the snack and the pita bread used wholegrain flours from two cereals – rice and pearl millet (Pennisetum glaucum (L.) R. Br.) – and two pulses – chickpeas and pinto beans. Depending on the product, the pinto bean content was changed. For the snack, the pinto bean content was maintained at 10%, while for pita bread it was 5%. Meanwhile rice, pearl millet and chickpeas were added in an equal ratio, which led to a product with a protein content of 12.8%, for the snack, and 10.5% for the pita bread. In both cases, the final products reached a mark of 70% in sensory acceptance. “This demonstrates good acceptance and indicates there will be considerable buying interest when the products are commercially launched. In addition to their protein content, another feature is the amount of dietary fiber, which reached 9% in the case of the snack, and 10% for the pita bread”, Piler adds. Raw materials consider market availability The choice of raw materials was based on the aspect of market availability, especially rice and pinto beans, which are two grains with substantial production in Brazil. Chickpeas were chosen in light of interesting qualities like their light color and reduced bean flavor, a trait that tends to cause some rejection among consumers. Piler explains that, in the case of pearl millet, the selection considered the fact that it is a cereal with outstanding nutritional characteristics due to the bioactives it contains, such as phenolic compounds, for instance. “In Brazil, pearl millet occupies over 4 million hectares in cultivated area, and it is mainly intended for crop rotation with soybeans and corn under no-till farming. Given those two nutritional aspects and planted area, using it entails higher food security through the availability of healthy food for human consumption”, he asserts. Thermoplastic extrusion The thermoplastic extrusion technology is known to medium and large-scale business owners in the food industry. According to the Embrapa researcher José Ascheri, it is a technological route that is less accessible for smallholders, as it requires considerable investment, which depends on the scale of production. “However, the products can be obtained from pre-installed production lines in large industries that process other conventional cereals like corn. This allows for diversification with alternative products, since millet, chickpeas and pinto beans are GMO- and gluten-free, and meet the healthy-food niche in convenience products”, he notes. Pasta with high protein and fiber content The gluten-free pasta is a product developed from whole pearl millet and chickpea grains, which results in a product with higher protein (13%) and dietary fiber (11%) contents than most commercially available products. The Embrapa researcher Melicia Galdeano details that the pasta development used a thermoplastic extrusion process to obtain pre-cooked mixed chickpea and pearl millet flour, and cold extrusion to shape (wire-draw) the final product. “In this case, fusilli, a corkscrew-shaped pasta, was obtained. The combination of technologies aimed to improve the product’s technological properties, as the hydrated pre-cooked flour forms a grid that mimics the gluten grid and improves the texture of the product. The active ingredient thus contributes to the offer of another food alternative for those with gluten and wheat intolerances, as it is a food with high fiber content and a higher protein content than other foods commercially available in the same category”, she adds. Partnerships The technological assets developed by Embrapa Food Technology are available for partnerships for the purposes of co-development, validation, industrial scale-up and licensing. The aim of such cooperation with the food industry is to perform tests for fine adjustments in the formulas and for the development of commercial products, in addition to the licensing and commercial exploitation of the co-developed product. Photos: Kadijah Suleiman

Photo: Kadijah Suleiman

![Kadijah Suleiman - New products like pita bread were obtained through thermoplastic extrusion, a quick and versatile manufacturing process Kadijah Suleiman - New products like pita bread were obtained through thermoplastic extrusion, a quick and versatile manufacturing process]()

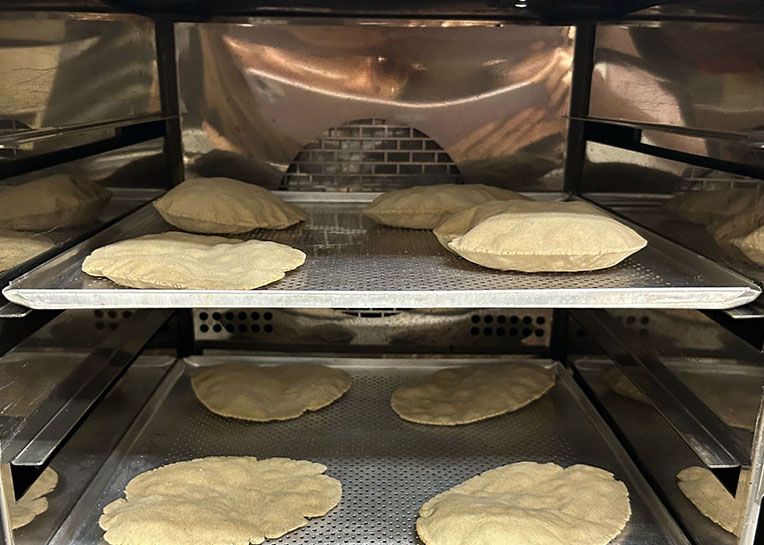

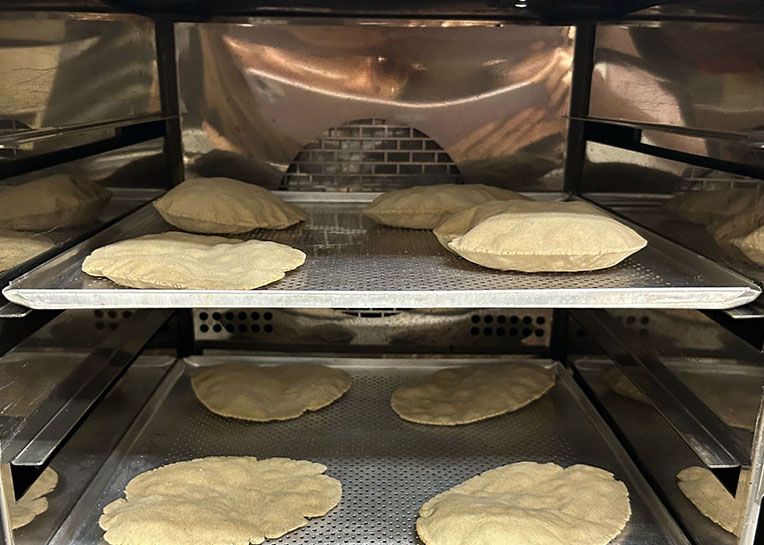

New products like pita bread were obtained through thermoplastic extrusion, a quick and versatile manufacturing process

Embrapa Food Technology is looking for partners to take new gluten-free food options, which combine whole cereals (rice and millet) and pulses (chickpeas and beans), to the market. The products include airy and crispy whole grain snack puffs; pre-cooked wholemeal flours for domestic or industrial purposes; whole grain pasta; and a pita bread formulation. Such technological assets are available for co-development, validation, industrial scale-up and licensing (See more details in the box at the end of this piece).

The results were achieved through the use of thermoplastic extrusion, a quick and versatile manufacturing process that forms different shapes and textures. According to the Embrapa researcher Carlos Piler, thermoplastic extrusion also allows the processing of the whole grains without separating them from their husks, as is the case in refined flours. As a result, the enzymes that cause rancidity are inactivated, extending product shelf life. “The choice of this process is strategic in the processing of whole foods, as the grains of cereals or pulses are fully used. Moreover, Embrapa has years of experience with the technology in the development of foods from a range of plant raw materials”, he informs.

The researcher also explains that both the snack and the pita bread used wholegrain flours from two cereals – rice and pearl millet (Pennisetum glaucum (L.) R. Br.) – and two pulses – chickpeas and pinto beans. Depending on the product, the pinto bean content was changed.

For the snack, the pinto bean content was maintained at 10%, while for pita bread it was 5%. Meanwhile rice, pearl millet and chickpeas were added in an equal ratio, which led to a product with a protein content of 12.8%, for the snack, and 10.5% for the pita bread.

For the snack, the pinto bean content was maintained at 10%, while for pita bread it was 5%. Meanwhile rice, pearl millet and chickpeas were added in an equal ratio, which led to a product with a protein content of 12.8%, for the snack, and 10.5% for the pita bread.

In both cases, the final products reached a mark of 70% in sensory acceptance. “This demonstrates good acceptance and indicates there will be considerable buying interest when the products are commercially launched. In addition to their protein content, another feature is the amount of dietary fiber, which reached 9% in the case of the snack, and 10% for the pita bread”, Piler adds.

Raw materials consider market availability The choice of raw materials was based on the aspect of market availability, especially rice and pinto beans, which are two grains with substantial production in Brazil. Chickpeas were chosen in light of interesting qualities like their light color and reduced bean flavor, a trait that tends to cause some rejection among consumers. Piler explains that, in the case of pearl millet, the selection considered the fact that it is a cereal with outstanding nutritional characteristics due to the bioactives it contains, such as phenolic compounds, for instance. “In Brazil, pearl millet occupies over 4 million hectares in cultivated area, and it is mainly intended for crop rotation with soybeans and corn under no-till farming. Given those two nutritional aspects and planted area, using it entails higher food security through the availability of healthy food for human consumption”, he asserts. |

Thermoplastic extrusion The thermoplastic extrusion technology is known to medium and large-scale business owners in the food industry. According to the Embrapa researcher José Ascheri, it is a technological route that is less accessible for smallholders, as it requires considerable investment, which depends on the scale of production. “However, the products can be obtained from pre-installed production lines in large industries that process other conventional cereals like corn. This allows for diversification with alternative products, since millet, chickpeas and pinto beans are GMO- and gluten-free, and meet the healthy-food niche in convenience products”, he notes. |

Pasta with high protein and fiber content

The gluten-free pasta is a product developed from whole pearl millet and chickpea grains, which results in a product with higher protein (13%) and dietary fiber (11%) contents than most commercially available products. The Embrapa researcher Melicia Galdeano details that the pasta development used a thermoplastic extrusion process to obtain pre-cooked mixed chickpea and pearl millet flour, and cold extrusion to shape (wire-draw) the final product.

“In this case, fusilli, a corkscrew-shaped pasta, was obtained. The combination of technologies aimed to improve the product’s technological properties, as the hydrated pre-cooked flour forms a grid that mimics the gluten grid and improves the texture of the product. The active ingredient thus contributes to the offer of another food alternative for those with gluten and wheat intolerances, as it is a food with high fiber content and a higher protein content than other foods commercially available in the same category”, she adds.

Partnerships The technological assets developed by Embrapa Food Technology are available for partnerships for the purposes of co-development, validation, industrial scale-up and licensing. The aim of such cooperation with the food industry is to perform tests for fine adjustments in the formulas and for the development of commercial products, in addition to the licensing and commercial exploitation of the co-developed product. |

Photos: Kadijah Suleiman

Kadijah Suleiman (MTb 22.729/RJ)

Embrapa Food Technology

Press inquiries

agroindustria-de-alimentos.imprensa@embrapa.br

Translation: Mariana Medeiros (13044/DF)

Embrapa's Superintendency of Communications

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/

For the snack, the pinto bean content was maintained at 10%, while for pita bread it was 5%. Meanwhile rice, pearl millet and chickpeas were added in an equal ratio, which led to a product with a protein content of 12.8%, for the snack, and 10.5% for the pita bread.

For the snack, the pinto bean content was maintained at 10%, while for pita bread it was 5%. Meanwhile rice, pearl millet and chickpeas were added in an equal ratio, which led to a product with a protein content of 12.8%, for the snack, and 10.5% for the pita bread.