Low cost nanosensor tracks fruits and monitors their quality

Low cost nanosensor tracks fruits and monitors their quality

|

A low-cost sensor embued with nanotechnology and artificial intelligence, capable of tracking and monitoring the maturation level of the fruits that ripen after the harvest – known as climacteric – , is the novelty developed by researchers from Embrapa Instrumentation, in the scope of an open innovation project with Siena Company. The tests were made with mangoes, papayas and bananas, but the sensor can be applied to several other fruits.

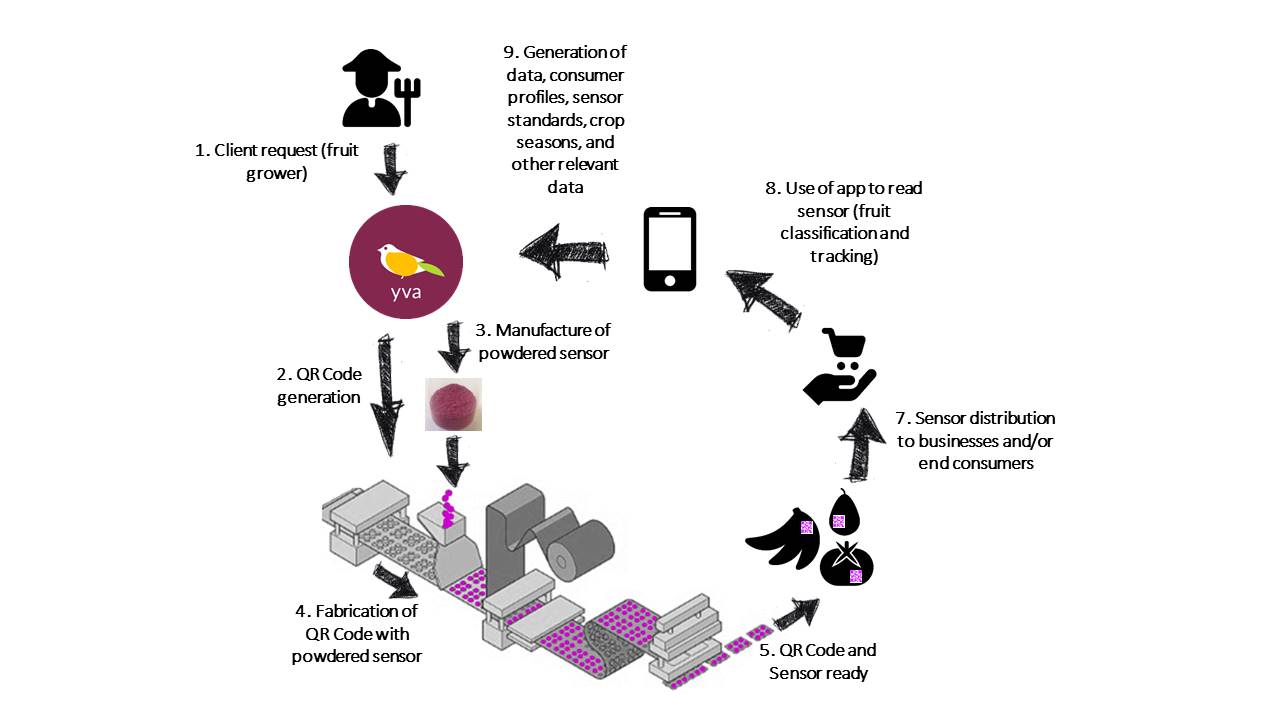

The colorimetric sensor called Yva (fruit, in Tupí-Guaraní) is similar to a QR Code label, which can be analyzed by any smartphone camera. It comprises a system to codify information through images, similar to an identification label, for the organization of contents on the web.

Yva is disposable and should reach the market with a cost estimated at between 8 and 10 cents of Brazilian Real per kilo of fruit. It detects the release of ethylene - natural hormone that is emitted as climacteric fruits ripen -, which, as it reacts with powdered nanoparticles, changes color, as the fruit ripens,

The change is interpreted through a mobile app, which either indicates when the fruit should be ripe and appropriate for consumption or indicates the specific point when it will reach the stage it is best appreciated by end consumers, among other functionalities.

Presentation to the marketThe nanosensor Yva will be presented, for the first time, at Embrapa's stand in Anufood Brazil, an international trade show for the food and drink sector. The business-oriented fair will take place on March 9 - 11, 2020, from 10h to 19h, at São Paulo Expo, in São Paulo-SP, Brazil. |

The nanosensor can be packed inside plastic bags or fruit boxes; it is aimed at several market segments, including, fruit farming and processing, wholesalers and retailers, associations, cooperative unions and exporting companies.

The versatility of the technology allows for different applications, including monitoring quality from the harvest to consumers' tables. It could also help the management of fruit stocks, according to the methodology used with perishables whereby the order the products leave storage follows the expiration dates for each product. It is known by the acronym FEFO (first expired, first out). The new technology should improve efficiency in the system and reduce foods loss.

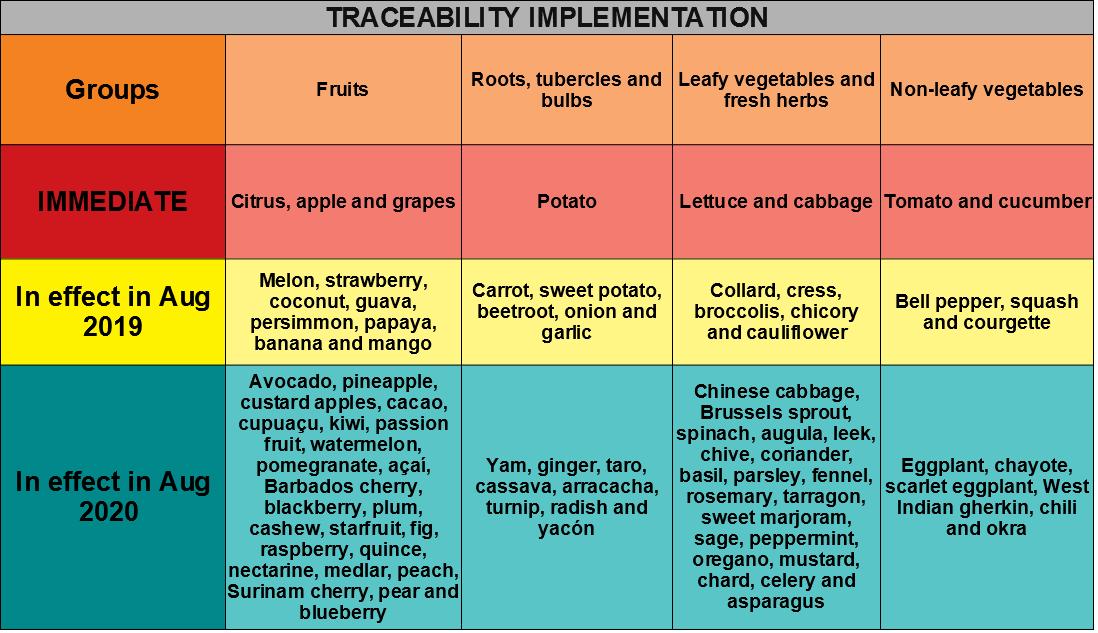

Yva can also aid compliance with Joint Normative Instruction no. 2, de fevereiro de 2018. from February 2018. Issued by the Ministry of Agriculture, Livestock and Food Supply (Mapa) and by the National Health Regulatory Agency (Anvisa) , it defines fruits and vegetable tracking procedures. It establishes food information recording in the establishments that participate in the production chain, from farmers to retail. This tracking protocol started with a few products and will be extended in August, according to the table below. The new technology is a cheap and useful tool to expedite this process, and simultaneously monitor fruit quality and maturation stage.

Less food loss and waste

The Yva sensor was developed with a focus on reducing food loss and waste in the course of the production chain. Brazil loses as much as 26 million tons a year, enough to feed 13 million people.

“New materials have extensively been tested to obtain the most suitable combination that would show color changes in the presence of ethylene, both in vitro and in vivo, and possible applicability in different fruits and systems”, explains the Embrapa researcher Daniel Corrêa.

“The technology has the potential to be applied to different climacteric fruits like peach, persimmon, plum, passion fruit, and others, but in the assessment we use mangoes, papayas and bananas, which demonstrated the sensor's efficiency, as it can be custom produced per user needs”, adds the other Embrapa researcher Marcos David Ferreira.

The team

The responsible team involved the researchers Marcos David Ferreira and Daniel Souza Corrêa, from Embrapa Instrumentation, while the project manager Ana Elisa Siena headed the QR Code software development - at the Siena Company - to allow lot-by-lot standardization of the sensor and offer fruit production traceability.

The project, which is due to last two years, counted on R$ 220,000 in funding from the Brazilian Technology System (Sibratec), an initiative of the Ministry of Science, Technology, Innovations and Communications (MCTIC), operated by the Studies and Projects Financing Agency (Finep).

The tests were conducted in the National Laboratory of Agribusiness Nanotechnology (LNNA), in São Carlos, a pioneer in the country and one of the eight strategic laboratories of MCTIC's National System of Nanotechnology Laboratories (SisNano).

Photo: Gabrielle Araújo

Specialized in software development and based in São Paulo state, the Siena Company has a Technology Operations Center in Campinas, and an Innovation Studio, in São Carlos, which supported the development of the app.

“What has been done so far is the so-called proof of concept for the technology. Now the challenge is the scale-up and the process of manufacturing the sensor, for which we need to raise R$ 700,000 - R$ 800,000 in funds so that the technology can effectively reach the market”, details Ana Elisa Siena, director of the Siena Company.

Some challenges the Yva sensor aims to respond to:

- Quality management - quality management and traceability are inefficient; despite the progress in the digital age, many still rely on paper-based controls;

- Identification of the optimal stage of the fruit - there are countless difficulties to identify the optimal point for harvest or processing, including the slowness in digitalization of data;

- High risk of human error - since the production chain still intensely relies on human effort (100% visual process), the data is subject to countless errors, losses and slowness.

Photo: Joana Silva

Increment to fruit farming for exports

The Yva sensor can contribute to adding value to fruit exports, and hence expand Brazilian fruit farming. The world's third largest producer of fruits, Brazil takes the 23rd place in the ranking of exporting countries, as it sells abroad only 2.5% of what it harvests, but the Brazilian Association of Fruit Exporting Producers (Abrafrutas) expects to open new markets and grow 15% a year for the next decade, through technological increments.

The global fruit market moves US$ 130 billion a year. This technology can add a differential to the products in the trade, with efficiency and competitiveness gains due to the quality monitoring and management.

To reach such goal, the country has invested in improving fruit quality aiming at the food safety standards required by the international market, a large consumer of mangoes (the most exported tropical fruit), papayas, bananas, and others.

Photo: Joana Silva

Testing and operation of the fruit ripening traceability and monitoring system

Translation: Mariana Medeiros

Joana Silva (MTb 19.554/SP)

Embrapa Instrumentation

Press inquiries

instrumentacao.imprensa@embrapa.br

Phone number: +55 16 2107-2901

Edilson Pepino Fragalle (MTb 21.837/SP)

Embrapa Instrumentation

Press inquiries

instrumentacao.imprensa@embrapa.br

Phone number: +55 16 2107-2807

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/