Intelligent fertilizer creates savings and minimizes environmental impact

Intelligent fertilizer creates savings and minimizes environmental impact

In the size of a rice grain, a controlled-release fertilizer developed with the use of the nanotechnology is the newest research bet to extenuate one of the biggest problems of applying nutrients to croplands: losses due to volatilization and leaching. The first relates to the transformation of fertilizers into gases, while the second refers to the product being carried by water, and both are responsible for losses to the extent of 50% of all the fertilizers that Brazilian farmers apply to their crops.

Tested in laboratory and in the fields, the intelligent fertilizer is less volatile than conventional urea, which in comparison usually volatilizes about half of the applied amount. The new product contributes to reducing greenhouse gases by two thirds of emissions from conventional fertilizer applications, and it can also be used as an animal supplement to increase the digestibility of forage. The new fertilizer is ready to be transferred to the private sector for adjustments to the stages of scale production and of trade.

Developed by Embrapa Instrumentation in partnership with Embrapa Southeast Livestock, the slow-release input differs from existing strategies because it puts forth a type of nanocomposite granule, through the physical mixture of a clay mineral that has been exfoliated in a nanoscale into the fertilizer matrix. Such strategy allows for greater control of the nutrient's release time and the possibility to include other compounds in its structure, including other types of fertilizers besides urea. The effectiveness of the new technology was proven by researcher Alberto Bernardi's team, from Embrapa Southeast Livestock.

Preventing losses of the input brings environmental and financial gains. Fertilizers represent 25% to 40% of the variable cost of the main agricultural production systems of the country, and one of the most important variables of such cost stems from the loss of large amounts of nutrients applied through fertilizers.

Research

The project, which was developed in the scope of the networks: "Nanotechnology applied to Agrobusiness" (AgroNano) and "Technologies for the increase of fertilizer efficiency and identification of alternative sources of nutrients for Brazilian agriculture" (FertBrasil), is the result of two studies, a Master's degree dissertation and a PhD thesis, which complemented each other for six years of research. It was supported with about R$ 400,000 in funds from the National Council of Scientific and Technological Development (Conselho Nacional de Desenvolvimento Científico e Tecnológico - CNPq), Coordination for the Improvement of Higher Education Personnel (Coordenadoria de Aperfeiçoamento de Pessoal de Superior Nível - Capes), Financier of Studies and Projects (Financiadora de Estudos e Projetos - Finep), São Paulo State Research Support Foundation (Fundação de Amparo à Pesquisa do Estado de São Paulo - Fapesp), and Embrapa..

The proposal by Cíntia Fumi Yamamoto and Elaine Inácio Pereira, both students of the Federal University of São Carlos (UFSCar), was to search for an alternative, but through different formulations, to nitrogen fertilizers, whose world consumption is mainly supplied by urea. Both studies concluded that it is possible to delay the release and reduce fertilizer losses from volatilization.

Heading the team responsible for the development of the new fertilizer, the Embrapa researcher Caue Ribeiro, coordinator of the AgroNano Network, reports that fixation methods that allow the prolonged release of nutrients in the soil can contribute to a more rational administration of fertilizers. The specialist refers to methods based on the association of lamellar materials or polymers.

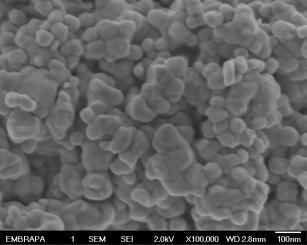

Ribeiro explains that the technology production process used a clay mineral whose structure comprises lamellae that are around 1-2 nm (nanometers - unit of length equivalent to one billionth of a meter, or 10-9 m) thick, exfoliated by the intercalation of fertilizer compounds such as urea. The new fertilizer was produced through a characteristic process of mechanical mixing and extrusion at low humidity, and the end product is composed of up to 85% of fertilizer mass.

The material leaves the extruder in the shape of filaments whose diameter is controlled according to the matrix in use, which are continuously cut into small granules of variable length as they exit the nozzle, and, after that, they are used white still wet or are dried outdoors in room temperatures. "After drying out, the material was cut, with the aid of a mechanical granulador, into cylindrical granules of aproximately 2.5 mm in diameter and 8 mm in length", the researcher recounts.

He also clarifies the fact that the end product presents mechanical resistance even when wet allows for adequate manipulation and distribution in the fields and dispenses with the drying process. "For storage and further use, if desired, drying can be made at room temperature, without driers or other processes, and without damage to the properties of the newly extruded product", he adds.

The fertilizer thus produced can be manually applied directly on the soil or through mechanized action. According to researcher, the process of slowly releasing the fertilizer or nutrient occurs due to two factors. The first one is a physical effect, the confinement between manometric lamellae promotes an increase in the time for the nutrient to diffuse into the medium.The other factor is the chemical interaction of the nutrient with surface charges of the clay mineral. "In the latter case, the release takes place through the dynamic of soil ions that were either present or were originated by plant activity. In the process, an ion in the soil replaces the nutrient between the lamellae, allowing it to be chemically desorbed and thus released," he explains.

Advanced techniques were involved to characterize the fertilizer nanocomposite, including X-ray microtomography, vibrational spectrophotometry by infrared, mechanical assays, as well as field experiments to measure emissions conducted in the Laboratory of the United States Department of Agriculture Agricultural Research Service in the city of Beltsville, in 2012, and soil incubation experiments held in the Laboratory of Soil Fertility and Plant Nutrition of the University Rakuno Gakuen, in Hokkaido, Japan, in 2013.

Nitrogen fertilizers

Nitrogen fertilizers are susceptible to losses by leaching, nitrate surface runoff, or through emissions of ammonia, nitric oxide, or nitrous oxide. Moreover, the efficiency of such inputs is currently low. The average percentages of fertilizer nutrients absorbed by the crops are between 50% and 70% of nitrogen, 15% and 30% of phosphorus, and 50% and 70% of potassium, according to the International Fertilizer Industry Association.

Although the maize, coffee and sugarcane crops represent about 71% of urea consumption in Brazil, the country cannot meet the demand from the domestic market, as the national industry faces challenges such as the competition from imported products, the low tariff barrier, tax cuts for imports, barriers for the expansion of fertilizer production due to the high prices of raw materials, the ICMS tax exemption for imports, and the high level of investment required to build new urea and ammonium sulphate plants.

Advantages

Among the advantages of the nanostructured fertilizer, the researcher highlights the development of a new product at lower costs due to the use of a national raw material that is largely available and innovative, once the material has not been used for such applications to date. The new product also has the ability to conform the material and intercalate the fertilizer in nanoscale simultaneously at temperatures that are close to room ones and with low moisture content, which dispenses with specific subsequent dehidration processes, preserving the intercalated fertilizer by preventing heating.

In addition, Ribeiro affirms that the granuled material is mechanically cohesive and geometrically compatible with practical application, i.e. manual fertilizer application methods or mechanized systems; conformation through extrusion allows the additional incorporation of different fertilizing elements in the process, which makes the granule or bead be representative of a formulation.

"As the base material is a clay mineral, there is a residual effect of the retention of water from rains or irrigation after the application and of other nutrients present in the soil through ionic exchange, considering that this is an intrinsic property of the raw material", explains the researcher.

Tests

The Embrapa Southeast Livestock and Embrapa Instrumentation assessed the performance of controlled-release nitrogen sources for use as fertilizers. The experiment examined the efficiency of the nitrogen from such new sources in plants, measuring losses in the the format of ammonia.

Nitrogen is an essential element for the plants. The lack of the substance can cause a halt in growth, yellowing of old leaves, and lower protein levels in seeds and vegetative parts.

Urea is the main form of nitrogen fertilization. The low efficiency of this fertilizer when it is applied on the soil surface is mostly due to the loss of nitrogen through ammonia volatilization. That is why it is important to develop new sources of more efficient fertilizers.

Efficiency tests were made with potted ryegrass for better observation of nitrogen levels, for approximately eight months at Embrapa Southeast Cattle's Greenhouse. The plant was chosen due to its high nitrogen requirement and capacity for resprouting. During the experiment, the ryegrass was cut six times. Thus it was possible to evaluate the residual effect of the fertilizer in the forage grass with precision.

According to the Embrapa researcher Alberto Bernardi, the new controlled-release fertilizer formulas proved to be efficient in the tests when compared to commercial fertilizers, and the plants, in every resprout, presented development and production that were equivalent or even superiors to those using traditional sources.

The next step for research will be to produce it in a larger scale and hold field tests with other crops, and for that purpose, it will be important to establish partnerships with companies.

Translation: Mariana de Lima Medeiros

Joana Silva (MTb 19.554/SP)

Embrapa Instrumentation

Press inquiries

instrumentação.imprensa@embrapa.br

Phone number: +55 16 2107-2901

Gisele Rosso (MTb 3091)

Embrapa Southeast Livestock

Press inquiries

pecuaria-sudeste.imprensa@embrapa.br

Phone number: +55 16 3411-5625

Further information on the topic

Citizen Attention Service (SAC)

www.embrapa.br/contact-us/sac/